Mechanical manufacturing wastewater

Industrial wastewater generated during the production and manufacturing of auto parts mainly includes degreasing wastewater, phosphating wastewater, anodic electrophoretic wastewater, topcoat wastewater, and charging room acidic wastewater. The wastewater is characterized by a wide variety of types, complex composition, irregular discharge, and large fluctuations in water quality and quantity.

Project Overview

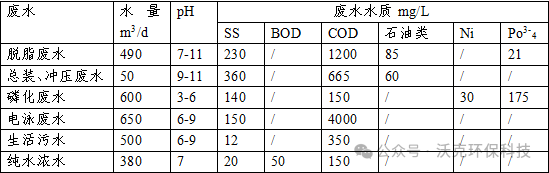

A certain automobile manufacturing enterprise has built a 2500m3/d wastewater treatment system to treat production wastewater and domestic wastewater. The water quality and quantity of various wastewaters are shown in the table below.

Process Flow

This project uses chemical pretreatment for multiple influents (precision punching, degreasing, electrophoresis) before discharging them into a mixed water pool for subsequent biological treatment.

Considering the diverse and complex chemical composition of the wastewater, its poor biodegradability, and site limitations, the biological treatment process adopts a "hydrolysis acidification + GMBR process". Hydrolysis acidification is frequently used in the treatment of high-concentration organic wastewater. By controlling the hydraulic retention time and the concentration of dissolved oxygen in the water, the anaerobic process of the organism is controlled at the hydrolysis and acidification stages, but it does not enter the acetic acid and methane production stages, thus shortening the reaction process and time.

The specific process flow is as follows:

Process Advantages

1. Efficient solid-liquid separation, strong resistance to shock loads, high-quality and stable effluent quality, complete removal of SS, good interception effect on bacteria and viruses, effluent can be directly reused;

2. Due to the high-efficiency interception of the membrane, microorganisms can be completely retained in the bioreactor, achieving complete separation of the hydraulic retention time (HRT) and sludge age (SRT) of the reactor, making operation control more flexible and stable;

3. High concentration of microorganisms can be maintained in the bioreactor, up to 20g/L or more, high reactor volume load, and the land area can be reduced to 1/3 to 1/5 of the traditional activated sludge method;

4. It is conducive to the retention and growth of slowly proliferating microorganisms such as nitrifying bacteria, improving the nitrification efficiency of the system. It can also increase the hydraulic retention time of some refractory organic matter in the system, effectively retaining the microorganisms that decompose refractory organic matter in the reactor, which is beneficial to improving the degradation efficiency of refractory organic matter;

5. GMBR processes generally operate under high volume load and low sludge load, resulting in low excess sludge production and reduced sludge treatment costs;

6. It can achieve fully automatic control and convenient operation and management.

Project Summary

This project involves high-concentration machining wastewater with diverse and complex sources. The process route of "fractionated pretreatment and combined biotreatment" adopted for this type of wastewater has certain general applicability. Currently, the project is operating stably, and the actual discharge concentration of pollutants after treatment is better than the local discharge standard.