Coal chemical wastewater case

Coal chemical enterprises generate a large amount of chemical wastewater during production, including gasification wastewater, coal-to-olefins (MTO) wastewater, wastewater from olefin production units, and domestic sewage. The wastewater usually contains complex organic pollutants such as polycyclic aromatic hydrocarbons, phenols, and biphenyls, making wastewater treatment challenging.

Project Overview: A coal chemical wastewater treatment project with a treatment scale of 25000 m³/d. Membrane module selection: GMBR flat sheet membrane, model GM480-3454, quantity 140 sets, 67200 square meters, flux 0.37 m³/m²·d

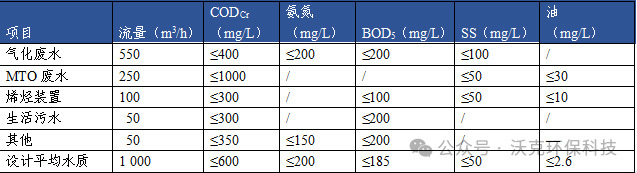

Design influent water quality:

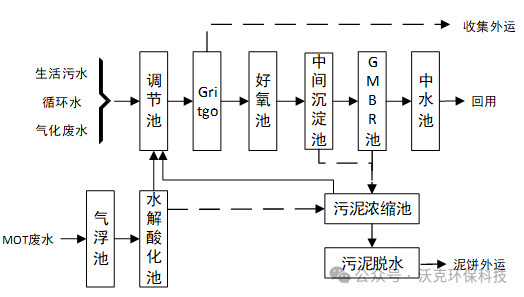

Process flow

Membrane process parameters

Submerged MBR membrane modules are installed in the membrane pool. The membrane has a pore size of 0.25 μm and a water production rate of 170~180 m³/set·d. There are 14 membrane pools, each with 10 membrane modules. Each membrane module has a membrane area of 480 m², and the total membrane area is 67200 m².

The GMBR process can achieve continuous and stable operation, solving problems such as large land occupation, large excess sludge production, and low removal efficiency in traditional biological treatment processes. It has broad application prospects.

Previous:

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.