Case study of aquaculture wastewater treatment

A 50 million broiler chicken farming project in the central Henan region features a 30,000m² hatchery with an annual output of 50 million chicks. Wastewater mainly comes from washing the egg trays, hatching baskets, and egg hatching trays; washing wastewater from transport vehicles; and a small amount of domestic wastewater. The main pollutants in the wastewater are broken eggshells, a small amount of egg liquid, chick droppings, and down; the concentration of suspended solids and the organic matter content are relatively high.

Engineering Design

Project Scale: 200m³ 3/d

Discharge Standards: Main indicators meet GB18918-Class A standards

Influent and Effluent Water Quality:

Unit: mg/L

| Item | C0D | BOD 5 | NH 3-N | SS | PH (dimensionless) |

| Influent | 1200 | 278 | 25 | 446 | 6~9 |

| Effluent | 50 | 10 | 5 | 10 | 6~9 |

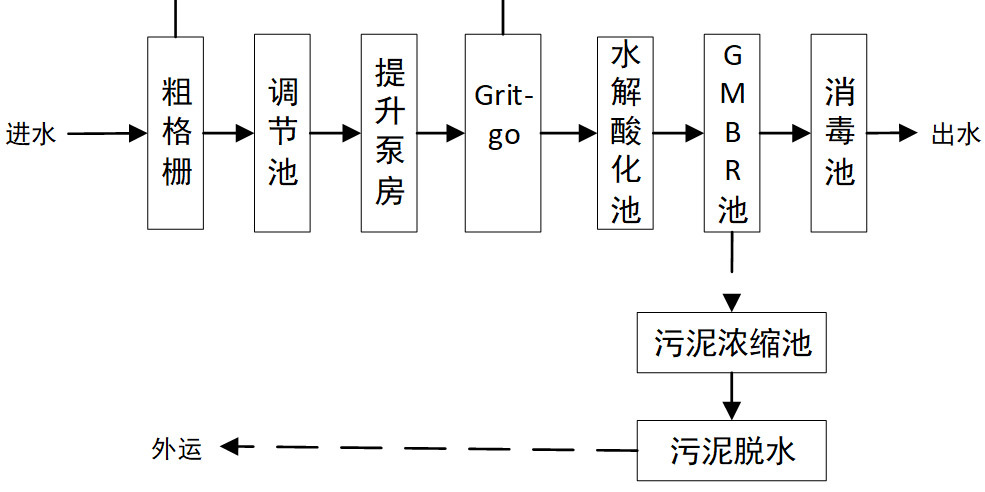

Process Design: Physico-chemical pretreatment + GMBR biological treatment process. The specific process flow is as follows:

Compared with conventional MBR technology, the hydrolysis-acidification-GMBR method has many advantages.

1. Gritgo pretreatment can intercept most solid substances and down, creating more stable operating conditions for GMBR treatment;

2. The hydrolysis-acidification stage can significantly degrade macromolecular organic matter, reducing the treatment load of the subsequent GMBR process and improving treatment efficiency;

3. Hydrolysis-acidification can improve the biodegradability of wastewater, making full use of the characteristics of acid-producing bacteria that have many species, grow quickly, and are highly adaptable to environmental conditions, facilitating the control of operating conditions: the addition of hydrolysis-acidification can reduce overall process operating costs;

4. Using GMBR flat membrane, CPVC membrane material is permanently hydrophilic, has a high flux, and is resistant to clogging. Virtual offline cleaning, simple and convenient cleaning and maintenance.

Main Process Parameters

Gritgo: LxBxH=1.5x1.2x1.5m; Aperture 0.2mm

Hydrolysis-acidification tank: LxBxH=10.5x3.0x3.5m; HRT=10h;

φ150mm combined filler: 54m 3

GMBR tank: LxBxH=10.0x3.0x3.5m: HRT=10h Membrane module model GM112, 6 sets, total membrane area 676 m² 2 Membrane flux 0.30m³/m²/d: 3/m2·d:

Design sludge concentration 6000~12000mg/L

Next: