Medical wastewater treatment case

Project Overview

This project mainly handles medical wastewater discharged from the outpatient building. The outpatient building wastewater discharge volume is 200m3/d.

Membrane module model GM96-1218, quantity 5 sets, 480 square meters.

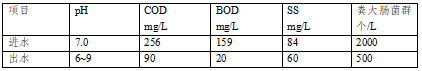

The design influent and effluent water quality of this project is shown in the table below:

Process Flow

This hospital wastewater treatment project uses GMBR technology, operating continuously 24h per day. The process flow is shown in the figure below:

After sedimentation and water quality and quantity adjustment, the wastewater enters the membrane bioreactor. Organic matter is degraded by microorganisms within the membrane system, purifying the water quality. The membrane's main function is to retain activated sludge, macromolecular organic matter, and bacteria within the reactor, ensuring the effluent water quality meets discharge requirements. Simultaneously, it maintains a high sludge concentration within the reactor, accelerating the biochemical reaction. The water exiting the membrane bioreactor is the treated effluent.

Technical Advantages

This project uses CPVC flat sheet membranes with a nominal pore size of 0.25μm. This pore size is far larger than the average virus particle size (200nm), meaning the membrane itself cannot retain viruses. However, virus removal is significant in the filtration effluent tests of the membrane pool. Therefore, during the wastewater filtration process of the GMBR flat sheet membrane, a dense biofilm layer forms on the membrane surface, reducing the pore size and achieving virus removal.

Previous:

Next:

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.